hardness test hrc|rockwell hardness testing machine diagram : OEM • Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more

CINESERCLA é um dos mais tradicionais grupos de cinemas do Brasil e mantém uma política de crescimento, com qualidade e eficiência em todos os seus complexos. Redes Sociais. Navegue. Institucional; Bomboniere; Corporativo; Promoções; Cinemas; Leis; Contato; Trabalhe Conosco; Perguntas Frequentes

{plog:ftitle_list}

26 de fev. de 2023 · Was erlebt die Seele nach dem irdischen Leben im sogenannten #Jenseits? Die Autorin und Bewusstseinsbegleiterin Jana Haas berichtet in diesem Talk mit Thomas.

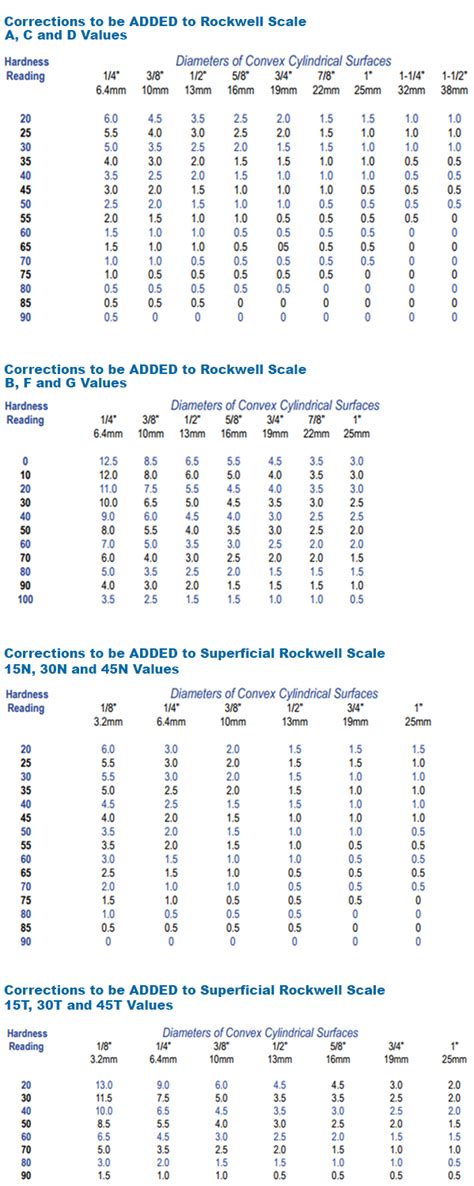

roundness correction factors chart

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use . See moreThe differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See moreThe Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See more

There are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more

rockwell superficial hardness tester

rockwell model 1900 hardness tester

• International (ISO)• US standard (ASTM International) See more• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See more

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test.

The most common is the static load indentation hardness test, such as Brinell Hardness (HB), Rockwell Hardness (HRA, HRB, HRC), and Vickers Hardness (HV). These hardness values indicate the ability of a . HRC: Diamond cone, 150 kg load, for harder materials. The hardness value is determined by the depth of the indentation. Vickers Hardness (HV): Suitable for microscopic analysis. Uses a diamond square cone indenter .The most common Rockwell method in practice is HRC. In principle, ball indenters are used for the hardness tests on softer materials and diamond indenters for testing harder materials. The diamond would destroy softer .

The connection between hardness and carbon content is clearly visible in the example below: the higher the carbon content, the higher also the HRC of various types of White Steel: White Steel 1 / 63 HRC / C = 1.25-1.35 % White Steel 2 / .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, .

node js 100 connection test package

The Rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. These materials often have high hardness levels and require higher applied loads to create an indentation. The Rockwell C scale (HRC) is commonly used for harder materials. Hardened Materials The Rockwell hardness test is less affected by .

Rockwell C HRC (120 degree cone 150 kg) Rockwell B HRB (1/16" ball 100 kg) Leeb HLD [1] 800-72-856 780: 1220: 71-850 760: 1210: 70-843 745: 1114: 68-837 725: . "Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness . After the preliminary test force has been applied for a short time, the dial gauge is set to zero (reference level). The actual hardness value can then be determined. Figure: Rockwell hardness test procedure. The actual test load F 1 is applied in addition to the preload and the indetor penetrates the material with the total force F=F 0 +F1 .Reference Table: Steel hardness conversion chart - all values approximate. Brinell Hardness HB Rockwell HRC Rockwell HRB Vickers HV N/mm²; 800: 72---780: 71hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell . point difference on the HRC scale is 0.5 on the HR30 N scale. Smaller differences in hardness can be determined using the 30 N scale. The above approach would also apply

by the Rockwell HRC and HRB scales for testing most steels, brass, and other metals. With the increasing use of materials other than common steel . is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in .International Standards Organization (ISO 6508-1 Metallic Materials) – Rockwell Hardness Test Part 1; American Standard Test Method (ASTM E 18) – Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials . Example 1: A regular Rockwell hardness method (HRC) 45 HRC. The number 45 represents the hardness value of the material.

Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. . The files are heat treated in 5 HRC increments, so you can start with the hardest file and work down until you get to one that skates instead of bites.Guides to Hardness Testing. Hardness Conversion for Rockwell C Scale or High Hardness Range . In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing.Hardness Conversion Formula. Y = aX^2 + bX + c. Where: Y is the hardness value in the target scale; X is the hardness value in the original scale; a, b, and c are constants determined through empirical testing; Example: Converting Brinell (HB) to Rockwell C (HRC) for steels:. HRC = -0.000000567 HB^2 + 0.0624 HB – 13.7. Using this formula, we can convert a Brinell hardness .

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .

International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale.

Rockwell hardness (HRC) = BHN/10-3 hardness measurement range: HS<100HB<500HRC<70HV<1300(80~88)HRA, (85~95) HRB, (20~70 )HRC In Rockwell hardness, A, B, C in HRA, HRB, HRC, etc. are three different standards, called scale A, scale B, and scale C. Rockwell hardness test is one of several common indentation hardness tests . One common grade is C, HRC, which uses a 150kgf total load and a 120° diamond cone indenter that is loaded twice. First, an initial load of P1=10kgf is applied to ensure proper contact between the indenter and the .

Regardless of its intended use, any good knife should have a hardness rating between 52 HRC and 64 HRC. Super-hard knives are great for kitchen duties where accurate, thin slices must be made regularly. Softer . The NIST HRC levels establish the hardness of materials slightly harder than the historical standards used in the United States for the past 75 years. The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell standards . Brinell hardness: Rockwell hardness: Rm: HV: HB: HRC: 250: 80: 76: 270: 85: . Types of Metal Hardness. According to the different test methods, there are three types of hardness. ① Scratch hardness. Hardness is primarily utilized to compare the resistance to local deformation of various minerals. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method.

Any value ranging in the mid-50s and above on the HRC hardness scale is considered hard. However, a high Rockwell hardness HRC number doesn’t necessarily mean it’s the best metal for a particular application. Superficial Scales. The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are .Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship among .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .The result is a dimensionless number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale. . There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). There are tables that are available correlating the hardness numbers from the different test methods where .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Hardness Calibration Test Blocks; Block Type: Test; Scale Type: Leeb D; Minimum Hardness: 40 HRC; Maximum Hardness: 45 HRC; Hardness Range Description: Mild MSC# 38443719 Mfr# 20-387-7That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History; . Rockwell C 150kgf(HRC) Vickers

rockwell hardness testing machine diagram

29 de set. de 2023 · ⚽ SE INSCREVA NO MEU NOVO CANAL:https://www.youtube.com/channel/UCmcr4LE0wj1E4D-Q_kr_mFw⚽ INSTAGRAM DO .

hardness test hrc|rockwell hardness testing machine diagram